The construction industry often overlooks a powerful, yet surprisingly adaptable, method from Lean Manufacturing: Single-Minute Exchange of Dies (SMED). Originally designed to drastically reduce setup times in high-volume production, SMED can be a game-changer for construction projects, cutting downtime and boosting productivity. This article explains what SMED is, why it matters, and how construction professionals can apply it to their work.

Зміст

Why Faster Setup Matters

In manufacturing, “setup” refers to the time it takes to switch a machine from producing one product to another. In construction, this translates to the time wasted between tasks: waiting for materials, reconfiguring equipment, or simply repositioning crews. These delays add up, inflating costs and slowing project timelines. SMED aims to minimize these non-value-adding periods, allowing teams to move seamlessly between operations.

The core idea isn’t necessarily to compress every setup to one minute (though that’s the ultimate goal in some cases). Instead, it’s about reducing setup times to under ten minutes—a “single-digit minute” target.

From Race Pits to Construction Sites

The principle is illustrated well by Formula 1 pit stops. Decades ago, changing tires and refueling took over a minute. Today, elite crews can complete the same task in under three seconds. This isn’t magic; it’s a result of meticulous planning, pre-positioning tools, and optimizing every movement. The same mindset applies to construction.

The Five Steps to SMED Implementation

SMED isn’t a one-time fix. It’s a systematic process of analysis and improvement. Here’s how to apply it to construction:

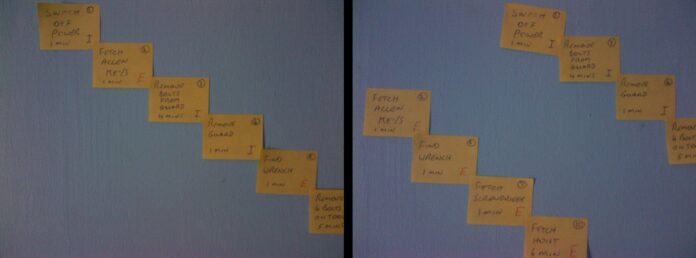

- Observe the Current Process: Video record the entire setup procedure for a time-consuming task. Identify every step, from gathering materials to final adjustments.

- Separate Internal and External Activities: Distinguish between tasks that must be done while the process is stopped (internal) and those that can be completed beforehand or during downtime (external). For example, prepping equipment off-site is external; adjusting supports on a crane is internal.

- Convert Internal to External: This is the key step. How can you shift tasks from being dependent on downtime to being completed in advance? Prefabrication, pre-assembling components, or staging materials strategically can all help.

- Streamline Remaining Internal Steps: Once you’ve externalized as much as possible, focus on simplifying the remaining internal tasks. Eliminate unnecessary movements, standardize procedures, and optimize workflows.

- Continuous Training and Refinement: SMED is not a one-time fix. Teams need training to execute new procedures effectively, and processes should be continuously refined based on feedback and performance data.

A Real-World Example: Underground Utility Installation

A project in Manchester, UK, applied SMED to streamline the installation of underground utility chambers. By reconfiguring site layouts, pre-positioning materials, and modifying equipment (like HIAB trucks), the team increased productivity by 167%—from 1.5 chambers installed in two days to two per day. This wasn’t a complex overhaul; it was a series of small, focused improvements.

Why SMED Is Overlooked in Construction

Despite its potential, SMED remains underutilized in construction. This may be because it’s often perceived as a manufacturing technique. However, the underlying principles—reducing waste, optimizing workflows, and minimizing downtime—are universal.

The Bottom Line

SMED is a powerful, yet often overlooked, method for improving efficiency in construction. By systematically analyzing setup processes and converting internal tasks to external ones, teams can significantly reduce downtime, increase productivity, and lower costs. The key is to recognize the opportunities and apply the principles with discipline and continuous improvement.

The industry needs more SMED success stories to demonstrate its value. The question is not whether SMED can work in construction, but why more teams aren’t already using it